Pioneering Dual Gradient Drilling (DGD) for safer, faster,

and lower-carbon wells.

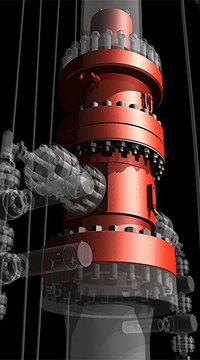

Reliable well control through Dual Gradient Drilling.

Overcome depth and reach limits of conventional drilling.

Drill wells in half the time and cost.

Reduce casing, cement, fuel and overall carbon footprint.

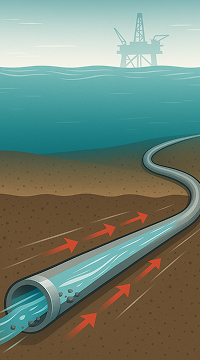

Conventional single-gradient drilling forces extra casing strings and shrinks final hole size, making ultradeep gas and high-heat geothermal targets uneconomic. In the Gulf of Mexico alone, more than 100+ Tcf of recoverable reserves have been identified — a potential 1 $ trillion opportunity — yet many projects such as Davy Jones and Blackbeard stalled due to the limits of conventional methods. Globally, over 400 ultra-deepwater wells (>2,500 m water depth) have been drilled in regions like Brazil, West Africa, and the Eastern Mediterranean, but the pace of development remains constrained by technical barriers.

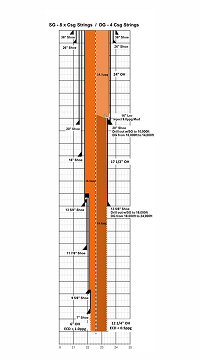

Ultradeep Dual Gradient Drilling (DGD) reshapes the downhole pressure profile to fit PP/FG, cutting casing requirements and preserving large bores. A DG well can reduce casing from eight to four strings and maintain a ~12¼″ hole at TD (vs ~6″ with SG). Lower ECD (<0.5 ppg vs >1.0 ppg in SG) minimizes losses and improves hole cleaning, while fewer casing/cementing cycles shorten well construction timelines by up to 50% and cut total costs by 30–50%.

By eliminating the chronic problems of narrow drilling windows, excessive flat time, and loss of bore diameter, DGD turns previously marginal ultradeep gas plays into viable developments and opens the door for scalable geothermal projects worldwide — the vision of «Geothermal Anywhere». At the same time, fewer materials and shorter operations deliver a materially lower carbon footprint for every well.

Safety | Emissions Reduction | Operational Efficiency | Sustainability | Extended Reach | Geothermal Anywhere

Reduce risk and cost by +30% of drilling HPHT wells

Allows for safe drilling of longer hole sections

Reduces number of casing

strings

Increases hole size

at depth

See how light and heavy drilling fluids interact in real time to reduce casing strings, extend lateral reach, and improve well control.

Dilution

Dilution  Extended

Extended  Well

Well  Optimized

Optimized Dual Gradient Drilling (DGD) reduces casing strings, preserves larger hole diameters, and eliminates flat time from repeated casing and cementing. The result: wells drilled in half the time, at half the cost.

DGD well design reduces well construction time by up to 50% and total costs by 30–50%

Requires multiple casing strings to safely manage pressure, leading to a much smaller final wellbore diameter. This limits completion options, reduces production efficiency, and increases drilling time and cost.

DGD preserves large annuli and final bore size, enabling high-performance completions in ultradeep gas and geothermal wells.

Longer horizontals, safer wellbores

Access reserves previously out of

reach.

Geothermal Anywhere